Resource Availability Planning

Ensures the availability of necessary equipment, people, and materials to meet production targets & operational needs

Streamlining Resource Planning for Operational Success

Resource availability planning plays a crucial role in the mining and metals industry. It ensures the availability of necessary equipment, human resources, and materials to meet production targets and operational needs. Effective resource planning increases efficiency, reduces costs, and improves sustainability. This article explores the key components and strategies of resource availability planning in the mining and metals sector.

Key Components of Resource Availability Planning

Equipment & Machinery

Maintenance Scheduling: Regular maintenance of mining equipment is vital to prevent downtime. CiteOps keeps track of equipment availability for mobile and fixed plant operations concerning maintenance needs through its Equipment Schedule feature.

Upgrades and Replacements: Plan for timely upgrades and replacements of machinery to keep up with technological advancements and maintain efficiency. CiteOps supports the planning of the availability of equipment for mobile and fixed plant operations regarding rebuilds and replacements through its Equipment Schedule feature.

Human Resources

Skilled Labor: Ensure that trained and experienced workers are available. This involves workforce planning, training programs, and retention strategies. CiteOps is market-leading in its ability to manage personnel rosters and people availability and qualifications for operations planning.

Health and Safety: Implement robust health and safety protocols to ensure a safe working environment, which helps retain staff and maintain productivity. With CiteOps availability planning, sites can ensure that work plans are adequately resourced. Plans can be built to ensure that the appropriate people and equipment can be resourced for the unique requirements of each job from a health and safety perspective.

Material Resources

Consumables: Items like explosives, lubricants, and safety gear need to be regularly tracked. CiteOps can track the usage of these consumables for each activity in the operational plan.

Strategies for Effective Resource Planning

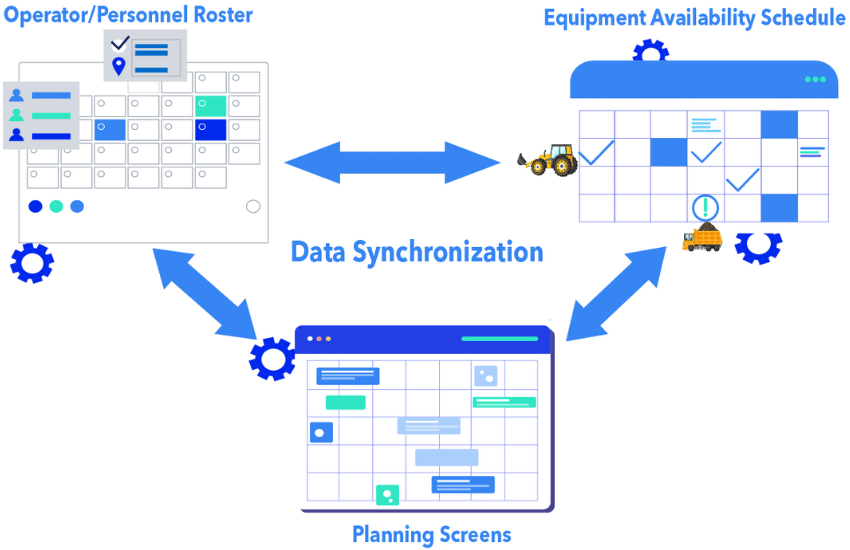

Integrated Planning Systems

Utilising integrated software solutions that combine various aspects of resource planning, from production management to workforce scheduling, provides real-time data and analytics for better decision-making. CiteOps uniquely integrates resource availability plans with operations planning and execution processes. All operational plans are driven by resource availability.

Collaboration and Communication

Enhancing collaboration between different departments and stakeholders is crucial. Regular meetings and communication channels ensure everyone is aligned with the resource planning strategy. CiteOps consolidates all operations into one central resource availability and operations planning platform, allowing teams to clearly understand resource availability across departments and to lend and borrow resources based on availability.

Risk Management

Identifying potential risks related to resource availability and developing contingency plans is vital. CiteOps clearly illustrates both resource availability and unavailability, as well as over and under-allocations of resources, helping to identify constraints and challenges that need addressing.

Final Thoughts

Resource availability planning is a dynamic and multifaceted process essential for the success of the mining and metals industry. By adopting integrated systems, data-driven decision-making, and sustainable practices, companies can enhance their operational efficiency, reduce costs, and ensure long-term sustainability. Effective planning not only addresses current operational needs but also prepares the industry for future challenges and opportunities.

15+

Mine Sites

5000+

Active Users

300+

Mobile Devices

1000+

KPI's Tracked