Short Interval Control

Optimise your operations planning across processes, teams, departments with smart control over resources.

Unlocking Efficiency with Short Interval Control

In today’s dynamic and fast-paced operations environment, Mining and metals companies are constantly seeking ways to enhance operational efficiency and productivity. Short Interval Control (SIC) emerges as a strategic approach to real-time management, enabling organisations to make quick, informed decisions based on up-to-the-minute data. This page delves into the concept of Short Interval Control, its key principles, and its impact on operational processes, including how Commit Works’ software portfolio supports companies in fostering an SIC approach.

What is Short Interval Control?

Short Interval Control (SIC) is a management methodology that focuses on monitoring and managing operations in short time intervals, typically ranging from hours to days. Unlike traditional long-term planning, SIC enables organisations to make rapid adjustments and improvements by closely tracking key performance indicators (KPIs) and responding to deviations.

Key Principles of Short Interval Control (SIC)

Continuous Monitoring

Defined Short Intervals

Decision Support

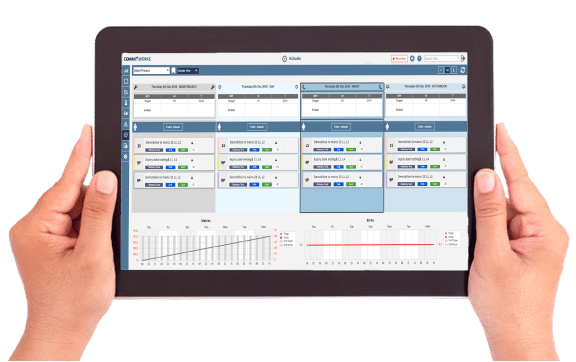

One of the core principles of SIC is the ability to take action when variations or issues are detected. This requires agile decision-making and a responsive organisational culture. Commit Works software brings visibility to progress of every shift, providing decision support for timely action. Planned vs Actual status of all work can be visualised on large screens in prominent areas of the operation, used to run regular performance review meetings, or monitored live on mobile devices.

Cross-functional Collaboration

The concept revolves around breaking down operations into short intervals, allowing for analysis and decision-making. These intervals may vary depending on the operation and specific processes but are typically shorter than traditional planning cycles. CiteOps can be implemented to support various levels of operations SIC maturity. This is achieved by complementing and replacing very basic paper processes, supporting feedback cycles received by control rooms on radio, and facilitating direct (in field) data capture on mobile devices or kiosks. Mobile devices moving in and out of connectivity can send and receive information on variable intervals based on their connectivity.

Continuous Improvement

SIC is not a one-time fix; it’s an ongoing process of continuous improvement. Organisations using this approach are committed to analysing results, learning from them, and implementing changes to enhance overall efficiency. Commit Works’ cloud software can be deployed to operations very quickly across initial target teams and workstreams, then extended across more teams over time.

What makes Short Interval Control a key capability?

Commit Works’ Short Interval Control (SIC) is pivotal for its ability to enhance operational agility and efficiency. By providing tools for continuous monitoring and decision-making, it enables companies to stay ahead of potential issues and optimise performance. Integrated into Commit Works’ software, SIC supports a dynamic approach to managing mining and metals operations, ensuring every decision is informed by the latest data.

Applications of Short Interval Control in Mining and Metals Sector

Mining & Production

Short Interval Control (SIC) is employed in mining to optimise production schedules, reduce downtime, and improve overall equipment efficiency (OEE). Timely data allows for better production planning and resource allocation. CiteOps software provides both planning capabilities and actual production data capture so that production schedules can be refined, realigned, and improved based on actual operations progress and feedback. CiteVis software provides real-time operations reporting capabilities so that all KPIs can be reported and visualised in various ways. Reports can be run on-demand and/or emailed automatically.

Project Work

SIC is valuable in project work to ensure that timelines are met, resources are utilised efficiently, and potential issues are addressed promptly. While SIC focuses on the detailed execution tasks of the shift, all of these detailed work tasks would be part of an overarching continuous or non-continuous production or project work process. CiteOps software keeps track of all of the details of the shift, but also how the shift plans and results impact statuses and progress of overarching plans. CiteOps ‘Jobs’ are designed to run across multiple shifts, and standard Jobs can be designed for standard processes.15+

Mine Sites

5000+

Active Users

300+

Mobile Devices

1000+

KPI's Tracked