Many mine sites are performing significantly below their potential.

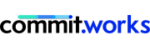

What we have observed is that those experiencing poor performance often think investing capital in technology or equipment is the solution. But they haven’t addressed the variability causing the poor performance, so they expand the operating envelope without solving the underlying problem.

David Upton was an Associate Professor of Technology and Operations Management at Harvard when he published a paper called ‘Mechanisms for Building and Sustaining Operations Improvement‘ which proposes:

The first thing to do is reduce variability within your operating envelope to improve average output. Then optimise processes to move performance up, maintaining the same disciplines to run the site with the same variability profile at a higher rate. Once the site hits a constraint, you can then look at capital investments to break the constraint to increase capacity to full potential.

Step 1. Get control to reduce variability

The first serious leap in productivity should come from eliminating day-to-day variability by ensuring that frontline teams have a well thought out plan to execute each shift. This is how Commit Works creates rapid, sustainable improvements in productivity, cost and safety.

Step 2. Optimise and improve processes

After you have successfully reduced variability, it’s time to build upon this and look at how you can improve further. This is when you might engage consultants to help, adjust shifts, modify equipment and make other changes to achieve even better results.

Step 3. Invest capital to increase capacity

After processes across the site have been streamlined, it’s time to leverage these positive changes. The final step of deploying capital allows your site to reach full potential – however it is vital that this final step is taken after the operation is running smoothly.